| Length | 12m(Customizable) |

| Height | 160mm(Customizable) |

| Material | 201 (1Cr17Ni5Mn6N), 202(2Cr13Mn9Ni4), 301 (1Cr17Ni7), 303(Y1Cr18Ni9), 304(OCr18Ni9), 304L(03Cr19Ni10), 316 (0Cr17Ni12Mo2), 316L (00Cr17Ni14Mo2), 321(1Cr18Ni9Ti), 420(2cr13), 310S (0Cr25Ni20), etc |

| Standard | ASTMAISI JIS.GB.DIN.EN |

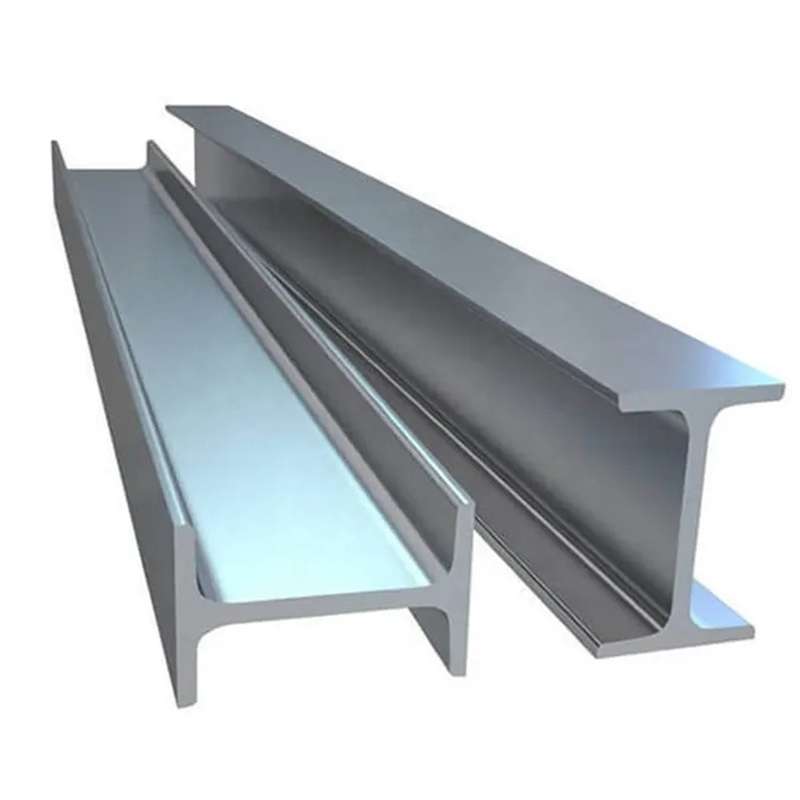

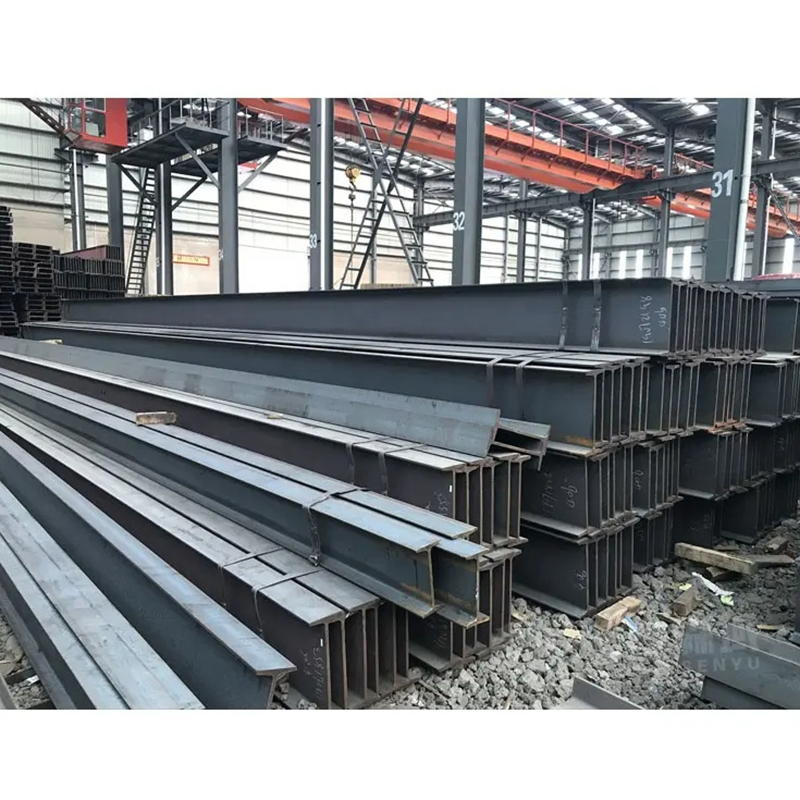

H Beam Prices Heat Resistant SS304 Grade Stainless Steel H

Shop for high-quality heat resistant SS304 grade stainless steel H beams at competitive prices. We are a reputable factory offering durable products.

Request a QuotePRODUCTS DETAILS

Hot Products

10mm deformed building concrete iron rod carbon steel

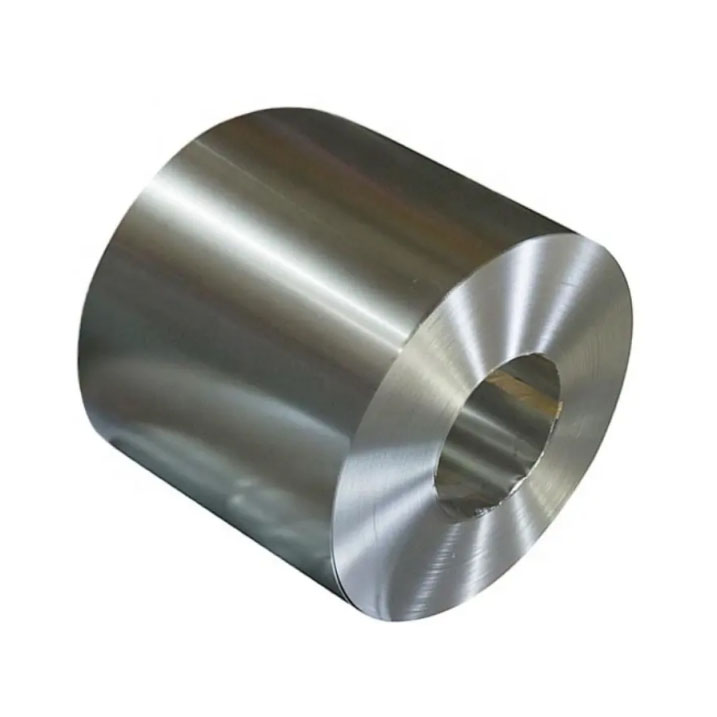

Gi Coil 0.16mm 0.20mm Gi Hot Rolled 55% Galvalume Steel Coil

Stainless steel rectangular tube / square tube

Copper Plate for Crafting and DIY Projects

High Quality Hot Sale 6mm Thick ASTM 304 904

Galvanized galvalume Aluminized zinc steel coil

High Quality Black Square and Rectangular Steel Pipes and Tubes

Secondary Grade Tin Coated Steel Tinplate Sheets and Coils for Oil

Premium Copper Strip for Industrial Use

Alloy Aluminum Sheet: Lightweight and Strong Material

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours